Boat Welding & Repair

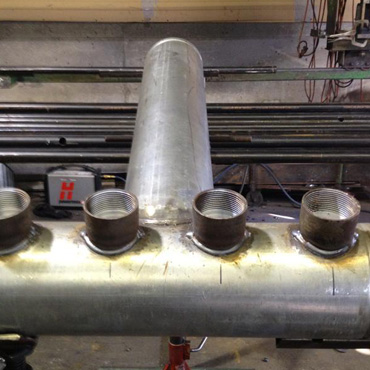

Bytown Welding provides boat welding that includes design and repair of boat elements, speed boats and pontoons as well as marina structural welding various boat related parts, frames and body in the Ottawa area. Aluminum alloys are lightweight and corrosion-resistant in marine environments, making the superior material for use in the shipbuilding industry.

About Boat & Marina Welding and Repair

When working on a boat repair, Probably the most important, and usually the first step in the repair operation, is identifying the aluminum base alloy being repaired. If the base alloy type is unknown, I would recommend contacting the original manufacturer of the component to establish the aluminum base material type. If the base material type is not available through a reliable source, it is impossible to select a suitable welding procedure. There are many different types of aluminum alloys, some have very good weldability and others have extremely poor weldability. Some can be welded with one type of filler alloy, and others may react unfavorably if welded with that same filler alloy. Unfortunately, if the base material type is not known, or unavailable, chemical analysis is the only one reliable way of establishing the exact type of aluminum alloy. A small sample of the base material must be sent to a reliable aluminum-testing laboratory, and a chemical analysis must be performed. Generally, the chemistry can then be evaluated and a determination as to the most suitable filler alloy and welding procedure can be made.

Boat Repair

It is very important to clean the repair area completely prior to performing the weld repair. This is typically achieved using a degreasing solvent to remove hydrocarbons followed by stainless steel wire brush to remove any hydrated aluminum oxide. More aggressive chemical cleaning may be required for some applications. In situations where it is necessary to remove existing weld or base material, in order to conduct the repair, you need to consider the methods available to perform this operation as well as their effect on the finished weld. If you need to remove a crack in the surface of a weld prior to re-welding, you must use a method that will not contaminate the base material to be welded. Care should be taken when using grinding discs as some have been found to contaminate the base material by depositing particles into the surface of the aluminum. Routing and chipping with carbide tools is often found to be a successful method of material removal.

2023 © Bytown Welding